In the world of construction and mining, anchoring solutions play a crucial role in ensuring the stability and safety of structures. Among various anchoring methods, self drilling anchor have gained significant attention for their efficiency and versatility. This article will compare self drilling anchors with traditional anchoring solutions, exploring their applications, advantages, and considerations for use.

Understanding Anchoring Solutions

Anchors are essential components in construction and mining, providing support and stability to structures. They can be classified into various types, primarily traditional anchors and self drilling anchors. Each type has its own set of benefits and limitations, making it important to choose the right solution based on the specific project requirements.

Traditional Anchoring Solutions

Traditional anchoring methods include various techniques such as driven piles, cast-in-place anchors, and screw anchors. These methods often require extensive excavation, which can be time-consuming and costly.

1. Driven Piles:

Driven piles are long, slender columns driven into the ground to provide support. This method is commonly used in deep foundation projects. However, it requires heavy machinery and can be limited by site conditions.

2. Cast-in-Place Anchors:

This method involves drilling a hole and pouring concrete to create an anchor in place. While this provides a strong hold, the process can be labor-intensive and may require more time than other methods.

3. Screw Anchors:

Screw anchors are helical devices that are twisted into the ground. While they offer good load-bearing capabilities, the installation process can still be slow compared to self drilling anchors.

Self Drilling Anchors: An Overview

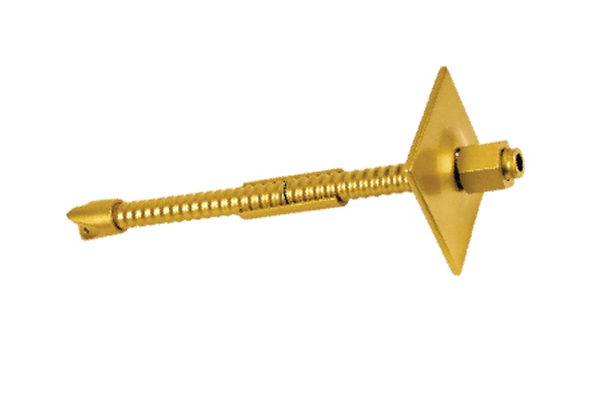

Self drilling anchors are specialized systems that combine drilling and anchoring into a single operation. These anchors consist of a hollow steel bar or rod that is drilled into the ground, often with the aid of water or grout, allowing for immediate load transfer.

Key Advantages of Self Drilling Anchors

- Efficiency in Installation:

Self drilling anchors significantly reduce installation time. The ability to drill and install in one operation minimizes the need for multiple steps and machinery. - Versatility:

These anchors can be used in a variety of soil conditions, including soft soils and fractured rock. Their adaptability makes them suitable for a wide range of projects, from mining to civil engineering. - Cost-Effectiveness:

While the initial cost may be higher than some traditional methods, the reduced labor and time requirements often result in lower overall project costs. - Immediate Load Transfer:

Self drilling anchors provide immediate load-bearing capabilities, which can be crucial in projects that require quick stabilization. - Minimal Environmental Impact:

The installation of self drilling anchors typically involves less disruption to the surrounding environment compared to traditional methods, making them a more sustainable choice.

Comparing Performance

When comparing self drilling anchors with traditional solutions, several performance metrics come into play:

Load Capacity

Self drilling anchors are designed to handle substantial loads, often exceeding the capabilities of some traditional anchors. Their performance in various soil types can lead to improved safety margins in construction projects.

Installation Speed

As mentioned, the speed of installation is a significant advantage of self drilling anchors. Traditional methods may require multiple trips to the site for different stages of anchoring, while self drilling anchors streamline the process.

Site Conditions

Traditional anchors may face limitations in challenging site conditions, such as unstable soils or confined spaces. Self drilling anchors can often adapt better to these environments, reducing the risk of project delays.

Applications in Mining and Construction

Widely used in mining and construction industries are self drilling anchors for drilling without the need for separate drilling equipment. In mining, they provide essential support for excavation and prevent ground collapse. In construction, they are used in retaining walls, slope stabilization, and foundation support.

Challenges and Considerations

While self drilling anchor offer many advantages, they are not without challenges. The initial cost of equipment and materials can be higher than traditional methods. Additionally, proper training is essential for operators to ensure effective installation.

It’s also important to conduct thorough geological assessments before deciding on an anchoring solution. In the selection process, these factors should be considered: soil conditions, load requirements, and project timelines.

The Role of Innovation

Companies like Argentium, a manufacturer and supplier of mining equipment, are at the forefront of developing advanced anchoring solutions. Their expertise in the field ensures that self drilling anchors are continually improving, enhancing performance and safety in various applications.

Conclusion

Choosing the right anchoring solution is crucial for the success of construction and mining projects. While traditional anchoring methods have served the industry for decades, self drilling anchor offer a range of benefits that are hard to overlook. With their efficiency, versatility, and minimal environmental impact, they represent a modern solution to age-old challenges in anchoring.

By understanding the differences between self drilling anchor and traditional methods, professionals can make informed decisions that enhance project outcomes. As the industry continues to evolve, embracing innovative solutions like self drilling anchor will be key to meeting the demands of modern construction and mining.